good-to-knows...

We must get a

bit technical now, in order to

better understand QRD design.

The N=number, the well-width, the maximum well-depth

and the chosen depth-sequence (M-number) are

essential designparameters for any QRD diffuser.

For a more technical and detailed article on design

and designparameters you may read:

"Evaluating

specifications and characteristics of QRD-Diffusers".

This article, in conjunction with the one you are

reading now, has everything there is to know about

simple yet very efficient acoustic diffusion at home.

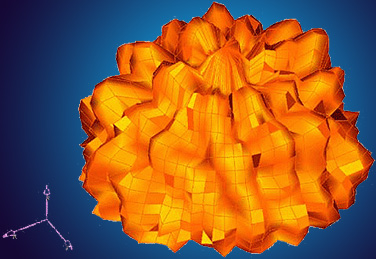

The N-number

of the

diffuser defines the number of wells per

period.

The

higher the N-number, the wider the working

range will be.

A correctly designed QRD-7

has a maximum working

range of 3,75 octaves, regardless

of any choice of other design parameters.

Well-width

defines the

upper frequency limit of the working range.

Narrow wells will result in a high upper

frequency limit.

This parameter is inextricably connected to

the chosen N-number: identical well-widths will

result in different upper limit frequencies when

a different N-number is chosen.

The maximum

well-depth defines

the lower frequency limit of the working

range.

Deep wells will result in a low bottom-end

frequency limit.

This parameter is also connected to the

chosen N-number:

identical maximum well-depths

will result in different lower frequency

limits when a different

N-number is chosen.

The chosen

depth-sequence (M-number)

defines depth and order of the various wells.

Each

N-number is accompanied by various depth-sequences.

Each of them will result in a

slightly different working range, which

always has a bandwidth of 3,75 octaves max.

Some N-numbers have only 2 or 3 depth-sequences,

others have 6 or 7, as you have read in the

table with prime sequences.

A designer chooses one of the available depth-sequences

within a given N-number.

Limitations...

To put it bluntly:

One cannot combine very narrow wells (to obtain a

high upper frequency limit) while at the same time

make those wells very deep so you can achieve a

deeper low-end limit of that working range.

It would be nice to create a very wide working range

this way, but it will not work out fine...

The thing is, within

those very narrow and very deep wells new unwanted

reflections, resonances and coloration will originate,

making the whole assembly quite useless for diffuser

purposes.

Correct

proportions between well-width

and maximum well-depth must be resprected to get a

succesful diffuser design, and therefore these

proportions are a crucial design parameter.

This proportion is related to the chosen N-number.

With a QRD-7 and a PRD-7 the

proportion is 1:4 maximum.

This

will result in a 100% efficiency benchmark that

corresponds, with a QRD-7, to a working range of 3,75

octaves.

A PRD-7 has a working range of 3,25 octaves at 100%

efficiency.

For example:

if you choose to apply a well-width of 5 cm, the

maximum well-depth will than be 5 x 4

= 20 cm.

If 20cm wouldn't suffice to meet a planned bottom-end

of the working range, you can choose a higher max.

well-depth of, let's say, 30cm.

30 cm divided by 4

results in a well-width of 7,5cm

which, in turn, will result in

a significantly lower limit for

high frequencies.

Yet in both cases we're dealing with a design of 100%

efficiency. Only the working ranges shift, defined by

either well-width or max. well-depth.

Choosing one always has consequences for the other.

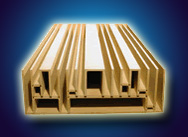

Plan - example

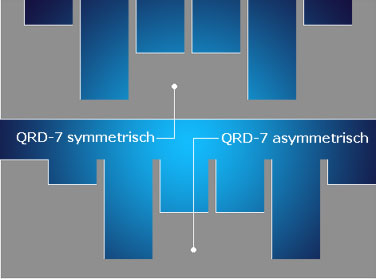

On the right an example of a QRD-7

plan.

Reading and interpreting it is probably no problem

now, when you have read this article up to this point.

The deepest well

in this example has been folded once to save space

and materials, yet the specs remain the same, with

or without folding.

This model is the FWD-36 diffuser, part of a family

of diffusers found elsewhere on this site.

This -36 is a fine allround diffuser!

Anti-flutter strip or Diffuser?

An FWD-36 diffuser has a well-width

of 36mm,

making it an allround diffuser with regard to the

working range.

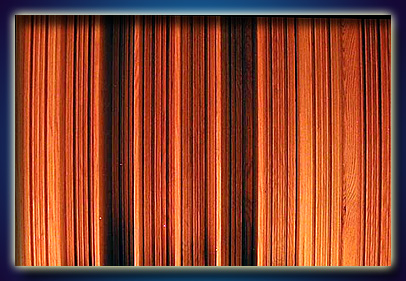

When the well-width of a

QRD-7 drops under 25mm

it

shouldn't be called a diffuser

anymore. A well-width of 25mm or less positions it in

the category of "anti-flutter

strips" of which 2 exponents are

shown on the right, a bit upward.

These are not really diffusers, because their working

range far exceeds the part of the frequency spectrum

where the fundamentals are found (which is up to a

little over 4kHz / c5 on the piano)

A well-width smaller than

25 to 30mm will position the upper frequency

limit of a QRD-7 a lot higher than the

top-end of the fundamentals range (a

little over 4000Hz.)

Such a QRD-7 can do wonders in eliminating local

flutter-echo and other

high pitched reflection problems

that are often a local phenomenon in a given room.

Such acoustic aids are referred to as "anti-flutter

strips".

The width of the fins -

6 and 4 mm combined in this example plan - should

never exceed 1/4 of the well-width.

Changing one dimension in the design will always have

an influence on other dimensions. Some of them can be

successfully compensated, like the width of the top-

and bottom plates or even the backwall.

Other dimensions, most likely

the maximum well-depth, can get

compromised, depending on the part(s) you plan to

modify.

Better also read the technical article, proposed here

earlier, before trying to alter a design.

TOP