ReadScapes

Evaluating specifications and characteristics

of QRD-Diffusers

|

|

Theory and practice differ in a diffuser in a way that, practically spoken, manifests as a huge advantage ! |

The

following considerations hopefully bring practically

useful insights in the acoustic

characteristics of QRD-diffusers. Specifications, reviews

and plans of such diffusers, found on this site, might

then be seen in a wider perspective. The fundamental fact is this: the practical working range of a given QRD-diffuser turns out to be about 1,75 times bigger than its theoretically calculated boundaries, and this is a huge bonus with useful implications ! Theory and practice differ here in a most beneficial way. From the beginning this phenomenon has been reported by all users. It was of course also noticed and investigated by manufacturer RPG, after which the phenomenon has been described in their deep-digging book on diffusers in 1990. Conclusion: your ears don't cheat at this point! A diffuser with sufficient maximum well depth (MWD) will also have a significant impact on low- and lower-midrange frequencies. Part of this extended range is not covered by the specs; it is well below the lower boundary of the working range... This is both quite obvious and useful. Realizing the full 100% of efficiency (more on this later on) should be inherent in a classic QRD-design, that has no dimensional restrictions. Such restrictions can easily occur in a diffuser that has a folded deepest well. While efficiency can be regarded as an indication of the quality of a given diffuser, it can only be interpreted as such, when read in the right context and with a correct sense of proportion. So please, continue reading. There's not a lot, but it's crucial in diffuserland. After reading this article, you will also find the DIY-page on folded-well diffusers easier to absorb. This page, written in English, can be found HERE. |

Working

Range -- theoretical and practical |

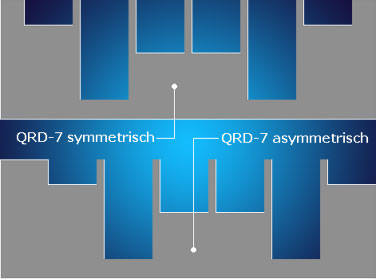

the four parameters of any QRD are visible in the image above a symmetrical and an asymmetrical version of a classic QRD-7 design |

Theoretical Working Range A diffuser's theoretical working range is a fundamental parameter that can be pre-defined. This parameter can be the most important criterium to choose a given model, but it can also make way for another aspect of equal or higher importance in a given situation, such as periodicity (more on this later). In a QRD-7 one period or panel width consists of 7 wells, separated by rather thin fins (they can be 'infinitely thin'). Most QRD's have symmetrical design. This means the odd 7th (non-deepened) well is divided in two equal parts. These half side-wells are then mounted as sidewalls with half side wells, together defining the 7th well. With classical QRD-designs, shown below left, the designer usually has a choice of different depth-sequences with each N-number. With a folded-well diffuserdesign only the use of unmodified depth-sequence is feasible. This imposes no limits on the design whatsoever, as an efficiency of 100% can be realised with almost any design. Below is an overview of all depth sequences of QRD-diffusers up to N=31. These are: QRD-7 / 11 / 13 / 17 / 19 / 23 / 29 & 31.

MWD

defines the theoretical bottom-end of

the working range

However, with

MWD of, let's say 25cm, the design formula will result in

a deeper bottom frequency with a QRD-7 than with a QRD-13!

Here we see the

same shift as with the MWD: a given well width in a QRD-7

will result in a lower top-end of the working range than

the same well width when applied in a QRD-17. And by

choosing different depth sequences, the same well width

will always result in different upper limits. |

an asymmetrical QRD-13 in real life and in sketch  With a QRD-7 design incorporating optimal proportions between SW and MSD and an unmodified depth-sequence the theoretical working range ALWAYS spans 2,75 octave regardless of the chosen SW or MSD |

The correct proportion between WW

and MWD can be compromised in two ways:

When

exceeding...

|

QRD-7:

max. 2,75 octaves |

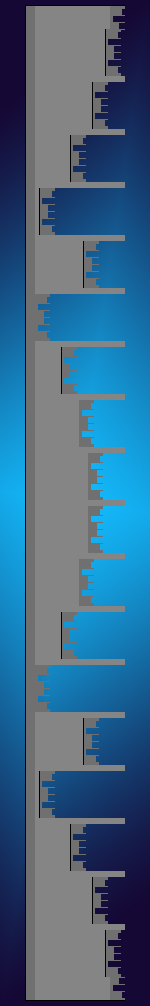

the practical working range of these 4 allround diffusers turns out to be 1,75 times bigger than the theoretical working range |

It became evident that only a QRD-11

would be feasible in the folded well concept. Higher N-numbers

are not really suitable for the trick with folded wells. This is not a problem in itself. Essentially you don't need more than good QRD-7's for homogeneous diffusion in the frequency range where it counts most -- the range of harmonics up to ±4kHz (c5 octave). On the left you see a table in which WW and MSD (in centimeters) of 4 allround QRD-7 diffusers is shown. Although the dimension for WW do not really differ that much, they still cover the complete range in which diffusion is normally desirable. Diffusers with high N-numbers will quickly encounter physical problems, when the rule of periodicity or 'repeating the pattern' is applied. The next section on "Homogeneous Diffusion and Periodicity" explains this parameter. And finally, you will need a lot more physical depth to create a QRD-11 that has diffusion down to 300Hz, than you need with a standard QRD-7! Practical Working Range Up to now we've always considered the theoretical working range of the diffuser. In all QRD7-4/7 mod.-0 models this range spans 2,75 octaves, corresponding with 100% efficiency. Lower and upper boundaries of the working range are defined by the MWD and the WW respectively, and they are the most important design parameters on the drawing board, as they define the target for the diffuser to be designed. From the practical application of diffusers -- starting slowly after the invention of the QRD-diffuser by Manfred Schroeder in 1972 -- it appeared the working range was clearly bigger than indicated by the design formula (theory). So much bigger that it is not just a little extra, but a real bonus. Under controlled and specific circumstances the performance of a diffuser surface can be measured and diagnosed, and these measurements support the finding heard.

This means the

practical working range of a QRD-7 with perfected WW /

MWD proportion spans over 4 octaves. This is wide enough

to span most of the sound- and space-determining

components of the soundfield in the lower midrange, the

midrange and sometimes quite a portion of the higher

midrange as well (in case of a narrow well width between

3 and 5cm), or an expansion at the bottom-end of the

working range, in case of a larger maximum well depth

exceeding 15 or 20cm. These variables can be found in the

table on the left. |

Homogeneous

Diffusion and Periodicity |

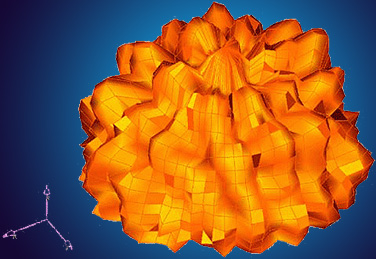

increasing degrees of homogeneous diffusion, visually projected |

Practice is a

lot more abstract though, because homogeneous diffusion

cannot easily be made visible, nor can it be measured at

home with a microphone and software on a laptop.

|

left: periodicity (5 x QRD-7) right: non-periodicity (1 x QRD-19) |

So

a given diffuser surface, regardless of its location or

purpose, is ideally 'covered' by at least three or four

joined diffusers or periods. Often the available physical width for diffusion purposes is limited. But even when this isn't really the case, any early reflectionzone in home-conditions requires not much more than 1,5 meter of diffuser treatment.

|

Efficiency |

high efficiency isn't the last word in quality of diffusion a design can deliver; efficiency says everything about the success of the proportion between the MSD and the WW |

After reading the information written above this section, on "Working Range" and "Periodicity", you will be able to appreciate the efficiency specs of diffusers.

A

diffuser with an efficiency of 50% can deliver totally

homogeneous diffusion, even if it is within a 50% reduced

working range. This working range will theoretically span

1,4 octaves, in case of a QRD-7, while it could also have

been 2,8 octaves. Yet within

this 1,4 octave of working range there is as much

homogeneous diffusion as with a perfectly designed

diffuser with an efficiency rate of 100% !

|

efficiency below 100% does not necessarily mean harm to the quality of diffusion itself; it just needlessly limits the maximum working range that's potentially possible with the design |

When

fysically designing a diffuser with folded wells, WW and

MWD must be manipulated in order to meet the desired

proportion, by applying various panel thicknesses, and

"fillers". Unfortunately, making-it-fit is

often not always

possible, at least not with a targeted well width, nor

with a slightly smaller or bigger well width, because not

all panel thicknesses are commercially available in MDF. top |

Frequently

Asked Questions |

There are not many, just a few quite important questions... |

stretching a diffuser with fabric leads to destruction of much of the diffuser's capacities, and creates many unwanted membrane absorbers, which is quite bad |

The

most important one is this: Can

diffusers be stretched with fabric ? Quite often the question raises whether diffusers can be stretched with fabric. Thus they become visually invisible. The question is very relevant, because the perspective of having to (spray)paint a collection of diffusers is usually not attractive.

By stretching

the front of the diffuser with fabric, no matter how

heavy or light, every deepened well becomes a small but

tuned absorbing element. Many small and powerful membrane

absorbers are thus created, and as there is a repeating

pattern of well depth, there is also a repeating pattern

of fully identical, selective, powerful and tuned

absorption. Unwanted absorption as well, RPG could

conclude and describe in their research on this.

Yet, the

potential of the diffuser will be compromised, no matter

how 'transparent' the fabric may be. In short: this is a

compromise one might be able to live with -- one that's

better than no diffusion at all. This cannot be said

about the first method of stretching the fabric directly

against the front of the diffuser. |

|

painting diffusers is usually not a job that brings lots of joy diffusers in MDF with lacquer carrying foil reduce the paintjob to just one layer of finishing paint painting will still be a drag, yet you should realise it is a one-time-only job... |

Logic

next Question: What IS the best way

to finish Diffusers ? The best way to finish diffusers is definitely painting or spray-painting. Both are one-time-only jobs, and so is normally the purchase of diffusers. They should last an audiophile life long. Many customers indicate this single labour investment is more than worth the effort, so they force themselves to painting for a long weekend (or two). Others prefer to do bussiness with a spray-painter. More expensive and with potentially better results than hand painting, although I have seen astonishing examples of home-craftmanship as well. No-finish is not an option. In dedicated listening rooms with somewhat dark moodlighting and brownish or other earth-like colours, an untreated but neat MDF diffuser might perfectly blend. However, if a lot of untreated mdf is present in the listening room, upper-mid and treble will suffer. In such cases a hard finish is unavoidable! In home-theatres the level of finish-in-black is often less critical. I've seen well finished diffusers with one layer of cheap black latex paint. Untreated (normal) MDF requires a ground-layer of paint, sometimes even two, although it might be too much asked in the case of decorating diffusers... A finish with rock-hard transparent paint for woodfloors is possible as well. It can be applied directly on untreated MDF or on top of a layer of colour paint. This paint is rock-hard, and the harder a diffuser surface is, the better its diffusing performance! In short: finishing the diffuser is in fact a must, also acoustically spoken. top |